Main Specification:

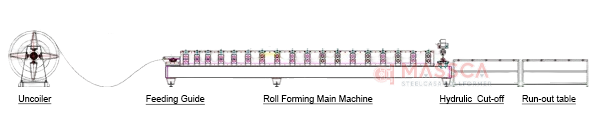

Production process flow:

Decoiler- Leveling device- Guide roller &Roll forming main machine-Hydraulic cut-off

Details of each component of 200B clip in linear strip ceiling roll forming machine

1. Decoiler

The decoiler is for uncoiling the strip raw materials coil. And it is manual loading and hydraulic expansion.

– Sheet width: less than 500mm;

– Inner diameter of material roll: φ508mm;

– Inner diameter expansion and contraction range ф480-560 mm;

– Maximum outer diameter of the material roll: φ1300mm;

– Carrying weight: ≤2T

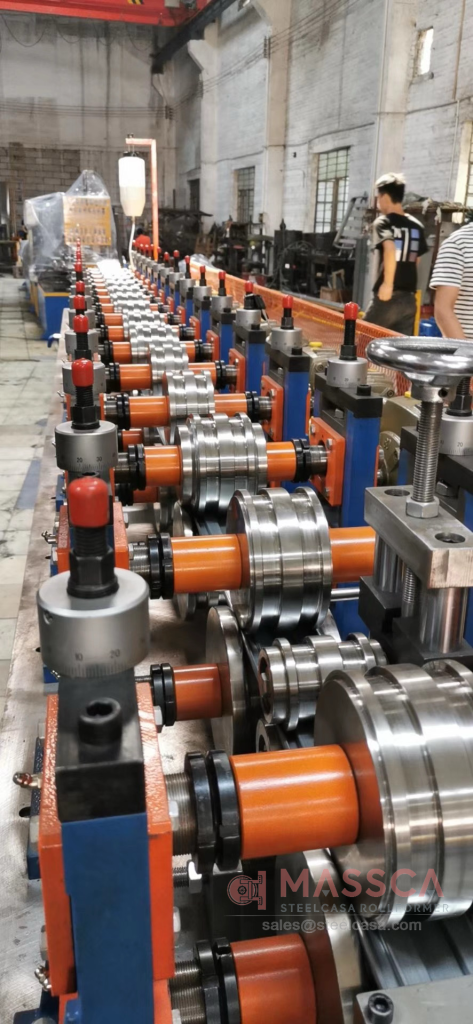

2. MAIN ROLL FORMING MACHINE

– Forming passes: 12-14 passes

– Combination form: wall panel type

– Side plate thickness: 22mm

– Forming specifications: according to drawings

– Transmission mode: gear transmission

– Forming frame: 10# channel steel

3. hydraulic cutting machine

– a. Form: hydraulic cutting off

– b. Cut off hydraulic capacitys: 20 tons

– c. Cutting mold: 1 set

– d. Structural features: The cutting machine is placed behind the forming machine.

The cutting tool material is made of high-quality tool material Cr12MoV, the cutting edge has no burrs and the tool has a long service life, and it can be replaced quickly.

4. The electrical control system

– There are two operation modes: manual and automatic. With manual and automatic

switching functions:

In the manual state, it can be operated as a stand-alone machine, which is convenient for

debugging and maintenance;

In the automatic state, the whole line of production runs and starts in sequence;

the entire line has an emergency stop button, which makes it easy to handle emergency accidents

and ensure equipment and Operator safety.

– There is a manual operation panel beside the machine to facilitate workers’ operation.

Application:

MASSCA ROLL FORMER is a professional manufacturer and supplier of molding machines in China, with rich experience in production and sales. Focusing on machine production and research and development for more than 20 years, the main products include drywall stud and track roll forming machines, U baffle ceiling roll forming machine, ceiling t bar roll forming machine and cable tray making machine, etc. welcome to contact us!