The MASSCA Ceiling T Bar Roll Forming Machine series consists of two machines. One of them is designed for the production of main Tee grids with a length of 3600mm, while the other is utilized for the automatic formation of Cross Tee bars with lengths of 600mm and 1200mm respectively.

Main Specification:

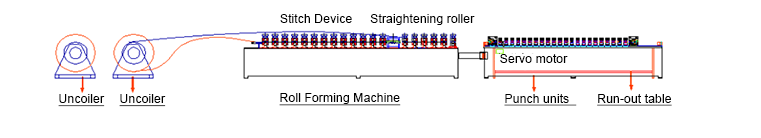

Production Process flow:

Uncoiler *2sets – Feeding guide & Roll forming main machine ( with sewing/Stitch rollers)- Hydraulic Punch Units

Installation Length: Spans 14.8 meters, designed to fit most production layouts

Details of each component of the T grid roll forming machine:

2. Roll forming main machine of the T bar line