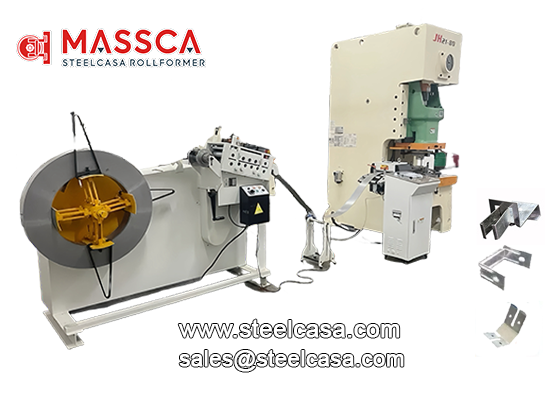

The combination of decoiler, leveling machine, punch press, and NC feeder is a golden combination. By changing the molds, different hardware stamping parts can be produced. This combination is widely used in industries such as suspended ceiling, rolling shutter door, and storage rack.

Main Parameter:

-Material: Galvanized steel

-Thickness: 1.0-1.5mm

-Product size and drawing details:

Each Component of the Punch line:

Function: Carry strip steel coil

Manually tighten and expand coil

Inner diameter of coil:

Max. Outer diameter of coil:

Capacity:1 ton

Leveling device: 7-axis straightening machine with 3 upper and 4 lower shafts.

2. Optional 40ton/63ton/80ton Punch Press

Nominal force: 400kN

Nominal stroke: 4mm

Slide stroke: 20-120mm

Strokes Per Minute (SPM): 55

Maximum mold installation height:220mm

Die height adjustment:70mm

Distance from slider center to machine frame:260mm

Worktable size: 480x710mm

Speed: 35-40pcs/min

Main motor power: 4 kw

Machine size: 1600x1180x2310 mm

3. Electric control box

PLC Control, HMI setting

Domestic Famous brand frequency converters for speed adjustment.

The electrical control box is equipped with a fully sealed ventilation cooling system.

The control system’s power supply features overload protection, and the electrical control panel is connected using aviation-grade connectors.