Description

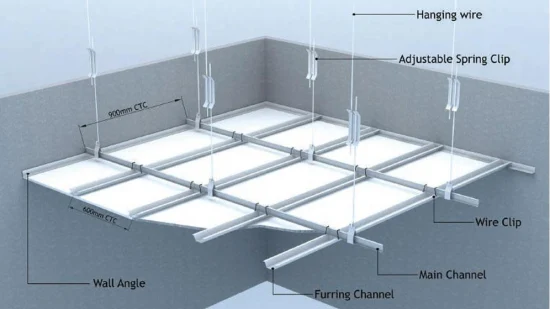

Furring channels, integral components of false ceiling hanging systems, are provided in conjunction with main channels and wall angle machines. These elements work in harmony to create a comprehensive and efficient framework for installing false ceilings. The furring channels, in particular, play a crucial role in providing additional support and stability, ensuring that the ceiling panels are properly secured and level. A reliable and aesthetically pleasing false ceiling structure can be achieved when combined with the main channels, which typically bear the majority of the weight, and the wall angle machines that help in the precise alignment and attachment to the surrounding walls. This integrated approach not only simplifies the installation process but also enhances the overall durability and functionality of the false ceiling system, making it suitable for a wide range of applications in both residential and commercial construction projects.

Furring system machine list:

| 1 | Furring channel roll forming machine |  |

| 2 | Main channel roll-forming machine |  |

| 3 | Wall angle roll forming machine |  |

| 4 | Wire-clip machine |  |

| 5 | Spring clip machine / Butterfly clip machine |  |

| 6 | Hanging wire-making machine |  |

Main Specification:

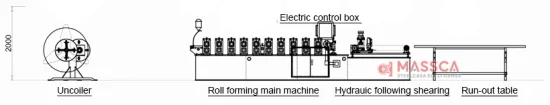

Production process flow of the

Uncoiler- Guide device & Roll forming main machine- Non-waste cutting – run out table

Details of each component of the roll-forming machine:

2. Main Roll Forming Machine

3. Hydraulic Shearing

Relative machine: