Description

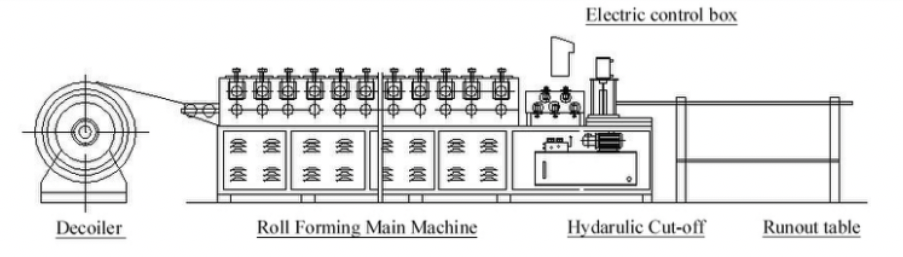

BARCING CHANNEL ROLL FORMING MACHINE

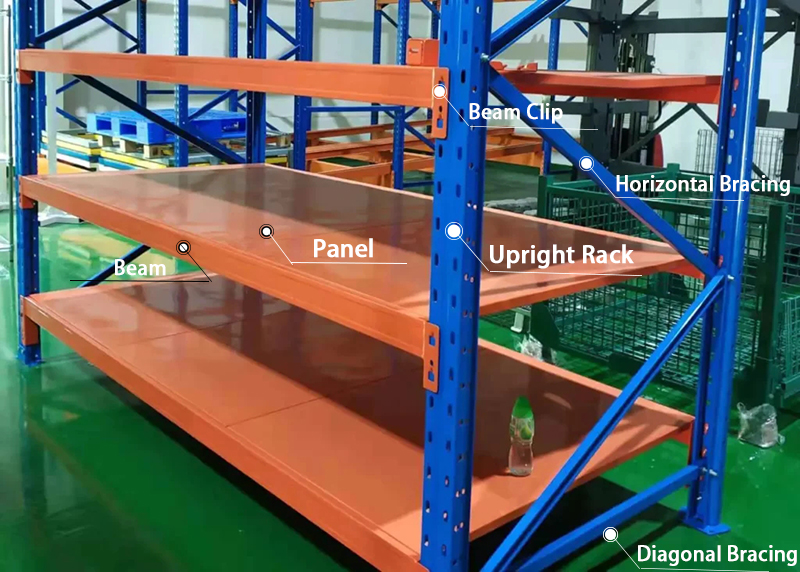

Bracing is a crucial component of pallet racking systems.

The bracing, including horizontal and diagonal braces, is used to connect the upright columns in a pallet racking system to provide stability and prevent the rack from swaying or collapsing. These braces help distribute the load and forces evenly across the structure, ensuring the safety and integrity of the rack.

Machine specifications:

Space needed: 15×2.5x2m (LXWXH)

Length Cutting tolerance:≤±1.0mm

Angle degree tolerance: ≤3°

Power supply: 380V 50Hz 3 Phs, Total power: about 11kw.

Hydraulic oil:46# hydraulic oil

Gear oil:18# double-line gear oil.

I Bracing Manufacturing Process:

Hydraulic decoiler——roll forming machine—hydraulic cut-off —run out table

II. Bracing Product Drawing

III. Main parameters:

i Hydraulic Decoiler 1 set

Coil outer diameter:1400mm

Coil inner diameter:470-530mm

Hydraulic for expansion

Coil width:300mm (max)

Weight capacity:≤3TON

ii Leveling machine 1set

(1) Max. Width 450 mm

(2) Max. Thickness 2.5mm

(3) Rollers for Leveling Ø 80 mm, 11 rollers

(4) Motor Power 3.0 kw

iii Roll forming Main machine

Roll forming roller: 14 Nos, straightening roller: 5 Nos

Material of roll forming roller: Cr12Mov

Heat treatment: HRC58-62℃

Rolling with heat treatment then finish processing

Incoming material: carbon steel , thickness: 1.3mm

Side board thickness: 35mm.

Bearing: HRB brand

Main motor: 5.5kw ,

Roll forming speed: 6-10m/min

Height adjustable by motorized

iv Hydraulic Cut-Off Device 4 sets

Cutting and punching combine mould: 2 sets.

Hydraulic auto cut-off and punch

vi Run-Out Table 1 set

(1) Structure rolling type table

(2) Length 6 Meters

vii Electrical control system

Plc control, length measured by the encoder.

Stop to cut off& bending

Frequency convert: Mitsubishi, Japan

Touch screen: Mitsubishi, Japan

Encoder: Omron

Other electrical components: Schneider

Rack System Main Components and Relative Machinery:

- Upright Rack

- Beam

- Plate

- Support Bar / Bracing-Horizontal & Diagonal Bracing

- Base plates and anchor

Reviews

There are no reviews yet.