Description

Full Automatic Aluminum Griliato Open Cell Ceiling Production Line

The Griliato cell ceiling, also known as an open cell ceiling, is a type of ceiling system characterized by its open and airy grid design. This design creates a visual effect of a lighter space while still providing substantial coverage for the ceiling area.

Main Specifications:

Material thickness:0.15-0.5mm

Profile width: normally 113mm,93mm

Speed:6-8m/min

Open cell ceiling machine process flow:

The Griliato Open Cell Ceiling Production Line is a specialized setup designed to manufacture griliato open cell ceilings, a popular style in modern architecture known for its grid-like, open-cell structure. This production line typically includes several key components:

- Decoiler: Unwinds the steel coil, preparing it for processing.

- Leveler: Flattens the metal sheet to ensure uniform thickness and surface evenness, which is critical for quality output.

- Punching Press: Equipped with custom dies, it punches specific patterns into the metal sheet required for the griliato design.

- Cutting System: Cuts the punched metal sheets into precise dimensions as per design specifications.

- Roll Forming Machine: Bends and forms the flat metal sheet into the final open cell structure, ensuring accurate and consistent cell shapes.

- Conveyor System: Transports the semi-finished and finished products between different stations on the line.

- Run-Out Table: Collects the finished griliato ceiling panels as they exit the roll-forming machine.

- Control Panel: Manages and coordinates the operation of the entire line, ensuring optimal synchronization and efficiency.

This machine is capable of producing items in a variety of sizes, such as 600mm, 1200mm, and 2400mm, among others, offering customers an array of production options through interchangeable molds. Both galvanized and pre-painted aluminum raw material coils are compatible with the Grilliato ceiling manufacturing equipment, enhancing its versatility and applicability across different project requirements.

Shapes We can make:

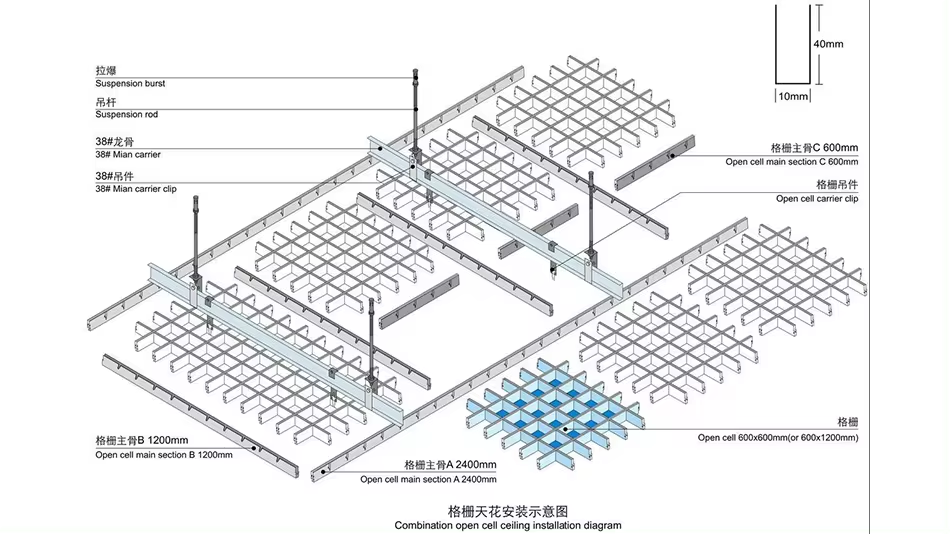

Installation guide drawing:

Application:

Reviews

There are no reviews yet.