Description

A ceiling T grid, also known as a suspended ceiling grid or drop ceiling grid, is a framework of metal or plastic components used to support ceiling tiles or panels. It consists of main runners, cross tees, and wall angles that are interconnected to create a grid pattern. This grid system provides a stable structure for installing and suspending ceiling tiles, allowing for easy access to the space above the ceiling for maintenance or repairs. Ceiling T grids are commonly used in commercial buildings, offices, schools, and other spaces where a suspended ceiling is desired.

Main Parameters:

- Raw Material: Pre-pained Steel 0.18-0.23mm, Galvanized steel 0.25-0.35mm

- Forming speed: 0-30m/min, speed is adjustable, Max.6-7pcs/min ( based on 3658/ 3600mm)

- Both metric and imperial products can be produced

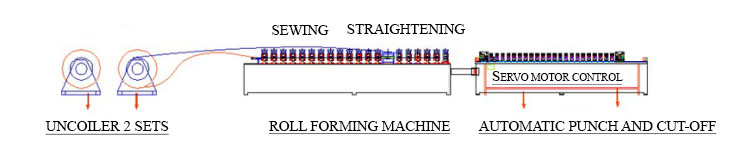

Production Process of Main Tee Bar Roll Forming Machine:

Uncoiler (2sets)- Roll Forming Machine-Automatic Punching and Cut-off after Forming- Finished Products

Main Components of T grid machine:

I. Decoiler 2 sets

Coil O.D 1200MM

Max. Outer diameter 1200mm

Inner diamter::φ450-530mm

Capacity: 500kgs/ Each Decoiler

Manual tension, with brake device

II. Roll Forming Machine:

Rollers: 18 groups forming rollers with feeding guide, 2 groups straightening device

Worktable : All-in-one structure, made by #45 steel, work table thickness:20mm, side wall 6mm

Material of roller: Cr12 Mov, hardness HRC55°, surface very smooth,will not scratch products

Roller Shaft: 40CR, Quenched and tempered, grinded, φ39

Machine frame structure: Pillar Rack, thickness 38mm, each group equip 8pcs Japan 6206 bearings. Surface with blackened treatment, long-term use and avoid rust

The main machine base is assembled from high-strength steel with precise welding treatment

Forming speed:0-30m/min

Product length: 3600mm

III. Driven Method

Driven by Gear / Chain Optional

IV. Hydraulic Punch and Cut-off

The punch die frame is made of #45 steel, all with fine plates and blacked on the surface

The punching die uses the material of SKD11 with vacuum heat treatment, hardness up to HRC58-60 degree, wear-resistance, good steel structure and long life use.

Punch die inserts can be quickly changed.

The punching die plate uses 50# steel, with fine plate treatment.

The punch unit worktable is a one-piece structure, with a worktable thickness of 20mm, a side thickness of 6mm

The hydraulic pump brand: Taiwan Kaijia

the oil valve: Taiwan Yutien brand

Oil pipes are made of steel wire and equipped with adaptable joints

Motor: 15KW all-copper wire temperature-resistant motor

Non-stop machine Punching the hanging holes and heads at one time.

Hydraulic cooling: Oil Cooling

Punching die:

| Head dies | 1 set |

| Tail die | 1 set |

| Middle hold die | 22 sets |

| Main grid High-pressure pipe | 2 pcs |

The safe cover is optional

V. Run-out table

Stainless Run-ou table

VI. Electric control

- Programmable controller 1set

- Industrial HMI 1 set

- Electric voltage: 380v 50Hz 3phase ( need customer confirmation)

Reviews

There are no reviews yet.