Description

MASSCA Pallet Upright Roll Forming Machine

The pallet rack upright roll forming machine is a specialized piece of equipment designed for the automated production of pallet racking uprights. These uprights are essential components in industrial storage systems. The machine allows for the precise and motorized adjustment of the rack upright’s width. The entire production line consists of various components, including:

- Decoiler: This part is responsible for feeding the raw material, typically steel coil, into the production process.

- Leveling Machine: This ensures that the steel coil is flattened and prepared for further processing.

- Power Press for Punching or Hydraulic Punching: This machine is used to create holes or slots in the uprights for attaching beams, brackets, or other accessories. It can be operated with either a mechanical power press or a hydraulic system, depending on the specific requirements.

- Roll Forming Machine: This is the central component of the production line. It shapes the flat steel into the desired profile for the pallet rack upright. The width of the upright can be adjusted automatically using a motorized system.

- Run-Out Table: Once the roll-forming process is complete, the uprights are conveyed to the run-out table for collection and further handling.

- Electrical Control Panel: This component controls and monitors the entire production line, ensuring that each stage of the process operates efficiently and accurately.

In summary, the pallet rack upright roll forming machine and its associated production line are crucial for the efficient and precise manufacturing of pallet racking uprights used in industrial storage systems. It offers automation and flexibility in adjusting the rack upright’s width, making it an essential tool for the storage and logistics industry.

Machine specifications:

Pallet racking upright roll forming line specification

Power supply 380v, 50Hz, 3 Phs

Roll forming speed 5-8m/min

Strip Material HR/CR rolled steel

Material thickness 2.0-3.0mm

Omega upright height 65mm

Omega upright width 90/100/115/125/145mm

I Pallet rack upright Manufacturing Process:

Material coil – Decoiling––leveling machine—Air clutch Power press (Yangli) for punching —Roll-forming machine– hydraulic cut-off – final profile

II Main parameters:

i Decoiler 1 set

(1) Coil width 350mm

(2) Inner Diameter Ø 440 – 500 mm

(3) Outer diameter Ø1200mm

(4) Max. Loading Capacity 5’000 kgs

(5) Manual operating type Manual expansion to tighten the coil

ii Leveling machine 1set

(1) Max. Width 450 mm

(2) Max. Thickness 2.5mm

(3) Rollers for Leveling Ø 80 mm, 11 rollers

(4) Motor Power 3.0 kw

iii 125 ton air clutch power press for punching (Yangli Brand)

(1) Servo feeder motor: 2.3kw

(2) Mould material Cr12Mov

(3) Mould heat treatment HRC 60-62℃

(4) Punching dies 4 sets

(5) Working pressure 125 ton

iv Main roll forming machine 1 set

(1) Roll Forming Stations 22 Nos.

(2) Width adjustable by motorized

(3) Roller Main Shaft Ø 85 mm, precision: ±0.02mm

(4) Side board thickness 55mm

(5) Roller’s Material Cr12mov, lathe finish with hard chroming.

(6) Roller’s Heat Treatment HRC 60– 62, precision: ±0.02mm

(7) Bearing 6310

(8) Roll Forming Speed 8 meters/minute

(9) Transmission part:

15 kw electrical motor 2 sets, equipped with JZQ 350 reducer 2 sets, and gear (1.5 inch, 12 gear) for transmission.

v Hydraulic Cut-Off Device 4 sets

(1) Cutting mould 4 sets, non-waste cutting

(2) Material of cutting mould Cr12mov, HRC60-62

(3) Hydraulic station working capacity 30 ton

(4) Hydraulic components Taiwan brand

vi Run-Out Table 1 set

(1) Structure rolling type table

(2) Length 6 Meters

vii Electrical control system

(1) PLC Mitsubishi, Japan

(2) Frequency convert 22kw, Mitsubishi, Japan

(3) Touch screen Mitsubishi, Japan

(4) Width adjustable By PLC

(5) Length adjustable By optical sensor

(6) Power Supply 380V, 50Hz, 3Phs

(7) Total power 40KW

(8) Total weight ≈ 12 Tons

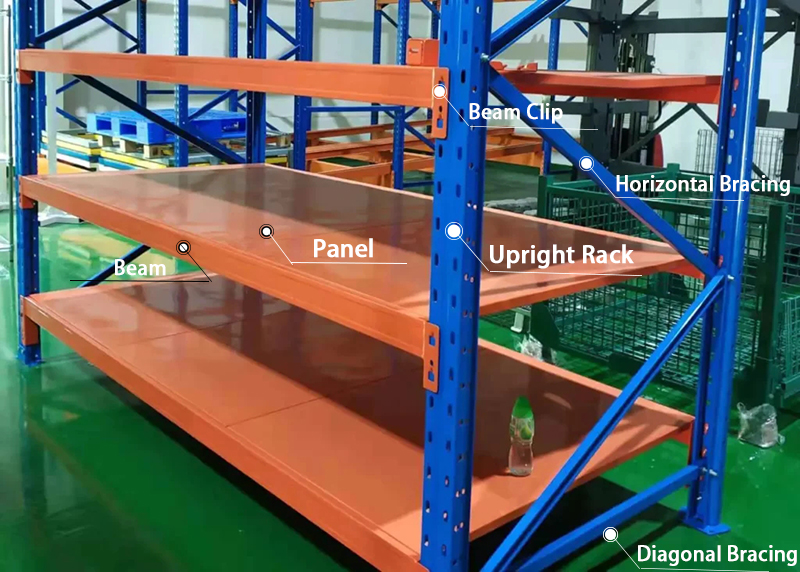

Rack System Main Components and Relative Machinery:

- Upright Rack

- Beam

- Plate

- Support Bar / Bracing-Horizontal & Diagonal Bracing

- Base plates and anchor

Reviews

There are no reviews yet.